Sampling is one of the fundamental processes for characterising a mineral deposit and is carried out at various stages in the evaluation and exploration of a mine. However, in order for important decisions to be made quickly, sample results need to be made available efficiently, especially in remote developments where transport can be an obstacle.

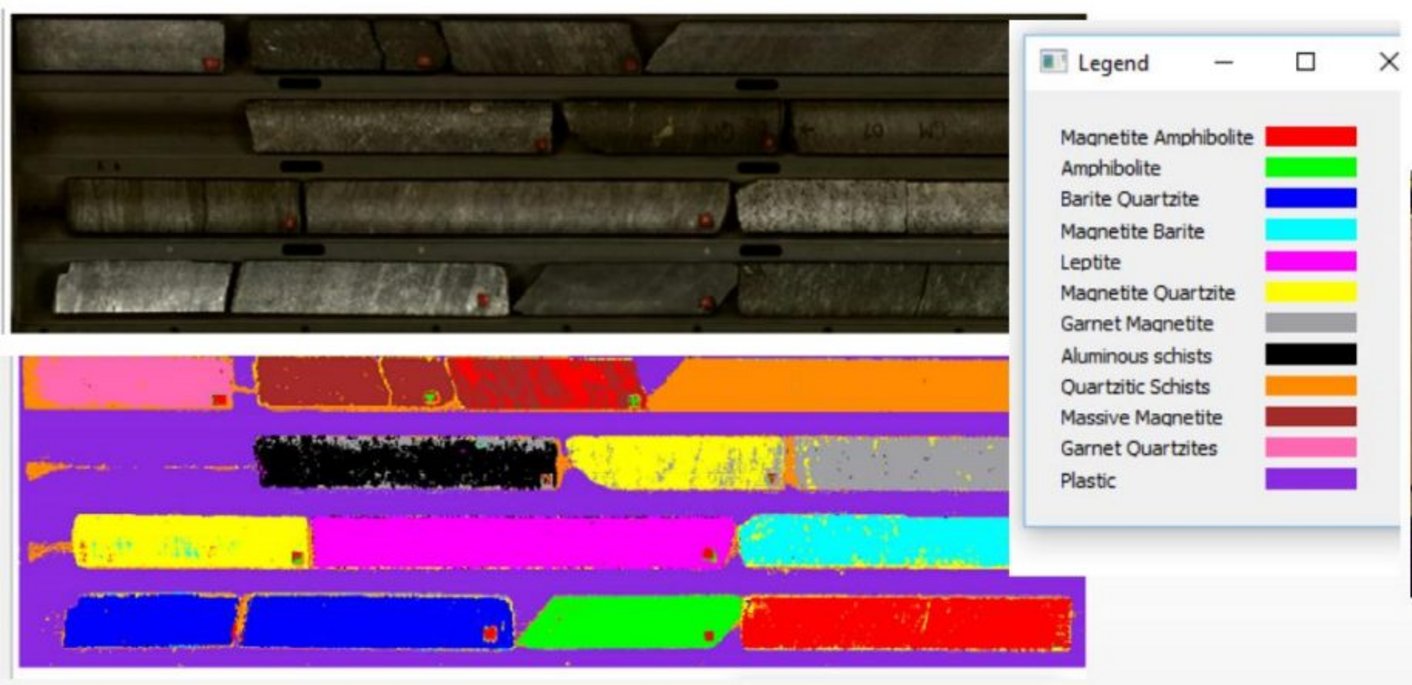

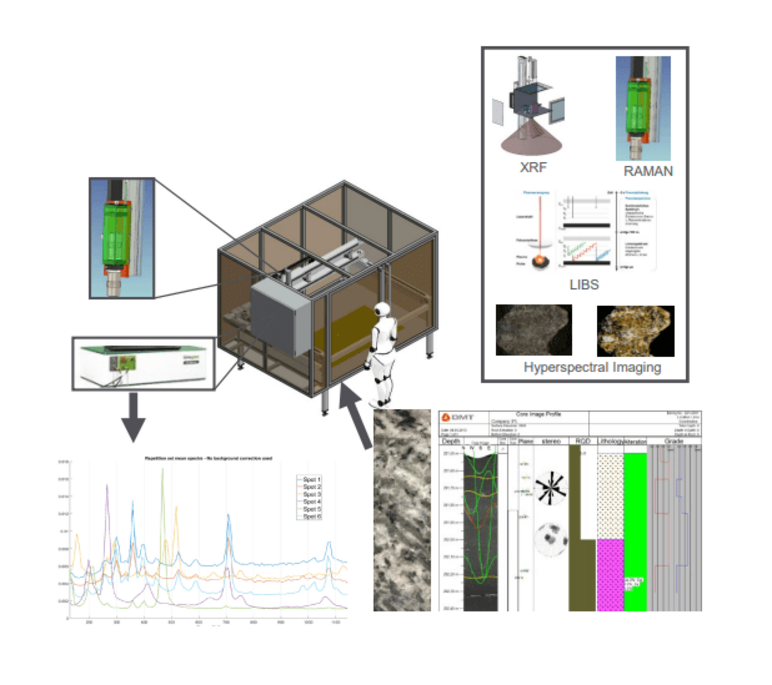

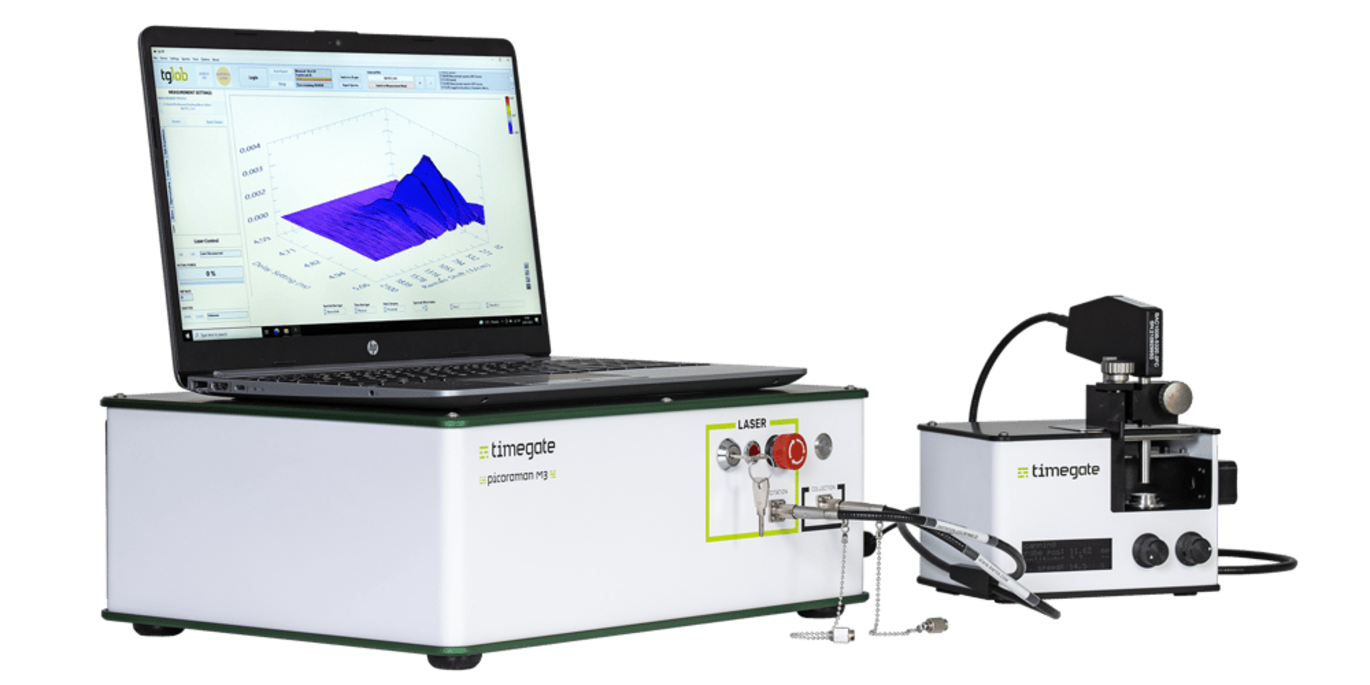

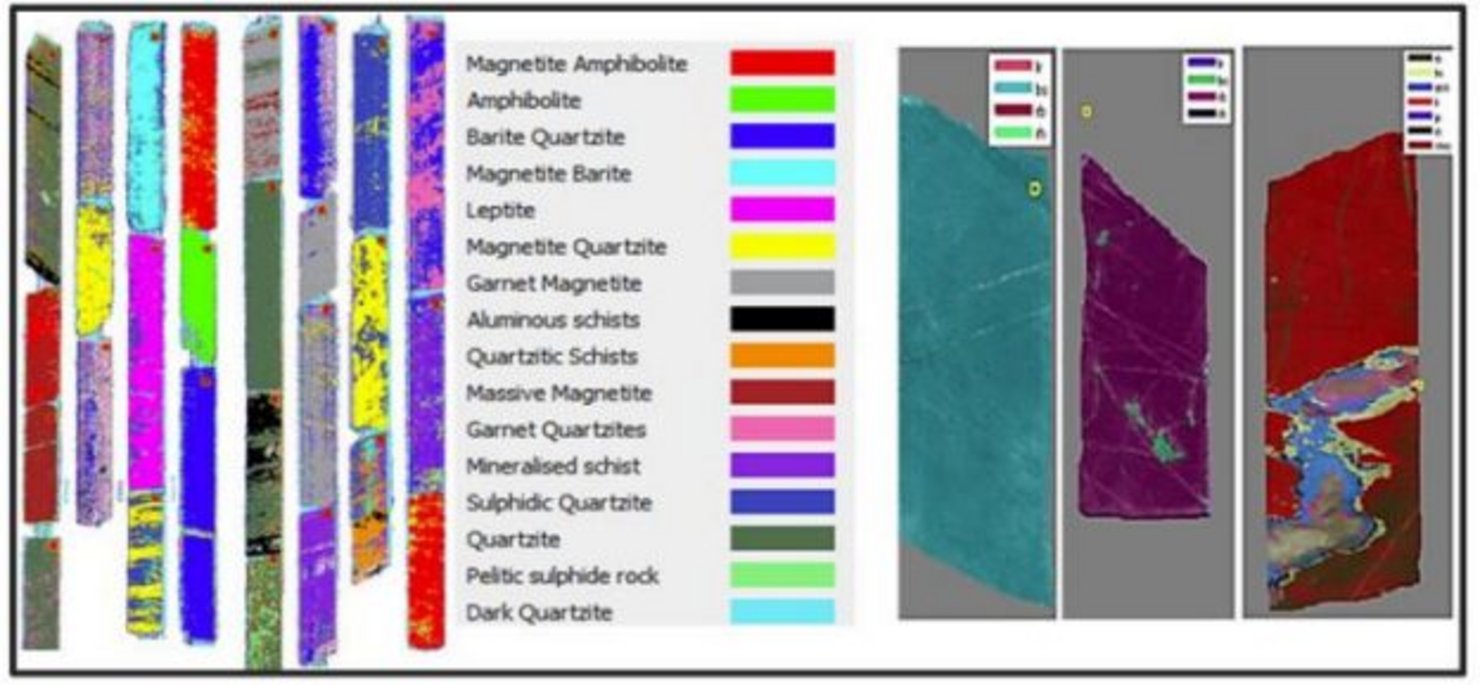

In order to minimise these problems, the DMT Group together with other partners, developed Ancorelog an analytical core drilling scanner system where results can be obtained in real time using a state-of-the-art artificial intelligence system. The algorithms transform the measured properties ("big data") into geological, geotechnical and geometallurgical properties ("smart data"), on site and in real time.

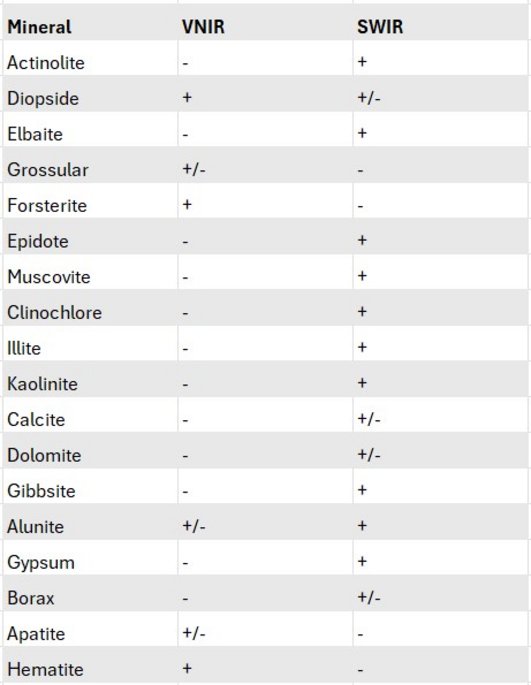

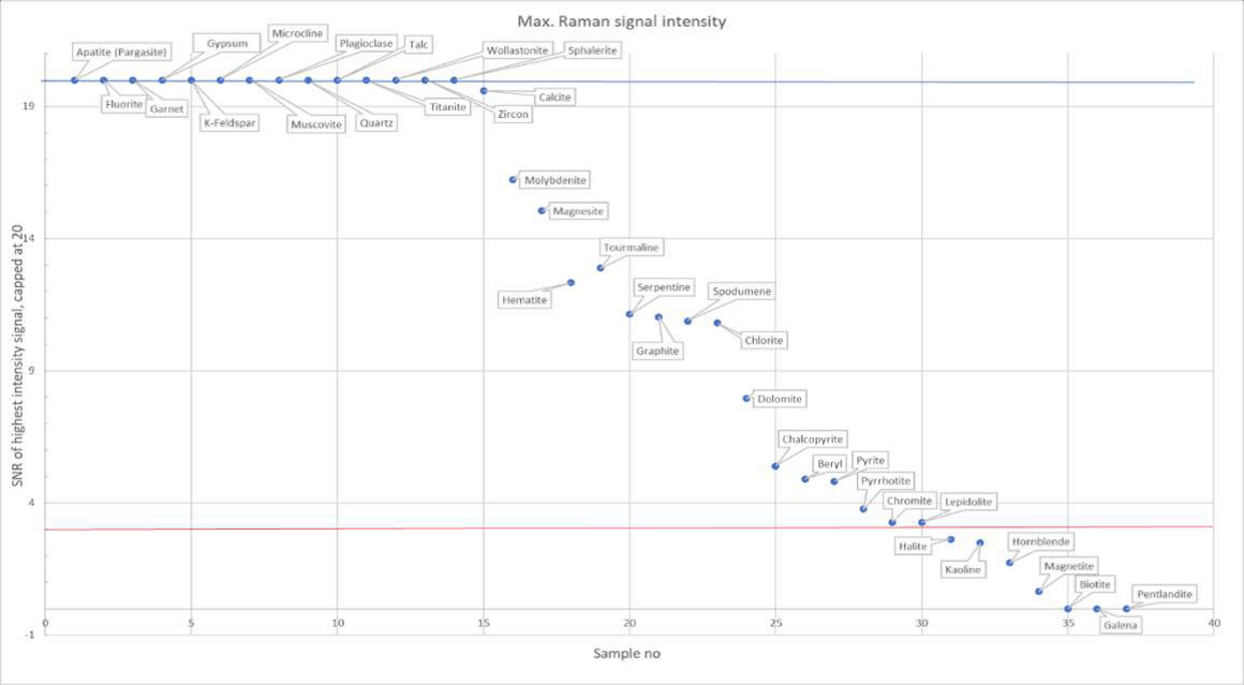

Because of its modular design, Ancorelog can be equipped with different combinations of sensors. The available sensors measure: the chemical and mineralogical composition of rocks, as well as lithologies and alteration zones.