The construction and use of thermonuclear power plants has expanded considerably since the 1960s, reaching almost 15% of all world production today, according to data from the World Nuclear Association (WNA). However, this percentage could grow with the construction of new plants, especially in developing countries.

According to data from the Brazilian Infrastructure Center (CBIE), in February 2019, the world's largest producer of nuclear energy was the USA, followed by France, Japan, Russia, South Korea and China.

In a current scenario, China has been standing out, being third in the world ranking. According to GlobalData, China is expected to overtake France as the world's second largest generator of nuclear energy in 2022, and by 2026, it will take over first place, which currently belongs to the USA.

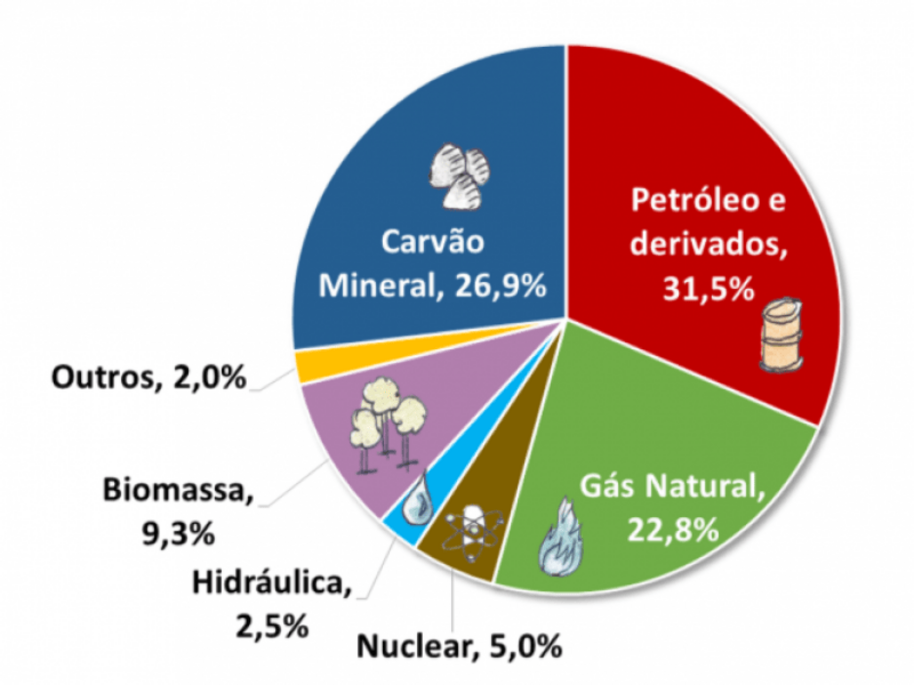

In global terms, nuclear energy ranked fifth in 2020, according to data from the International Atomic Energy Agency (IAEA), shown in the graph below. The prospect is that this percentage will increase with the growing concern to reduce emissions of polluting gases, as well as with the expansion of the technology, mainly by China.