The future of mining points to a trend towards increasingly continuous and automated processes, aiming to meet the growth in global demand for mineral commodities. The deployment of automated systems has increased mine productivity and safer operations by reducing operators' exposure to the daily risks of a mine. The Kiruna Mine in Sweden stands out among mines with autonomous operations, leading the way in the application of underground technologies.

Thus, Kiruna stands out in terms of autonomous and modern mining, as well as acting as a testing ground for several equipment manufacturing companies, such as ABB, Epiroc, Combitech and Sandvik. It is currently considered the second largest underground mine and the largest underground iron mine in the world.

In today's text, we will address:

- Kiruna Mine

- Kiruna: Automated operations

- LKAB Project 5.0

- Reconstruction of Kiruna

Kiruna Mine

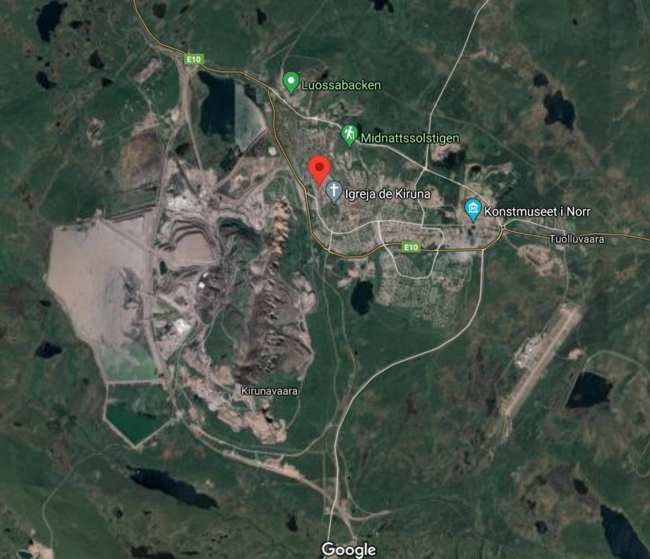

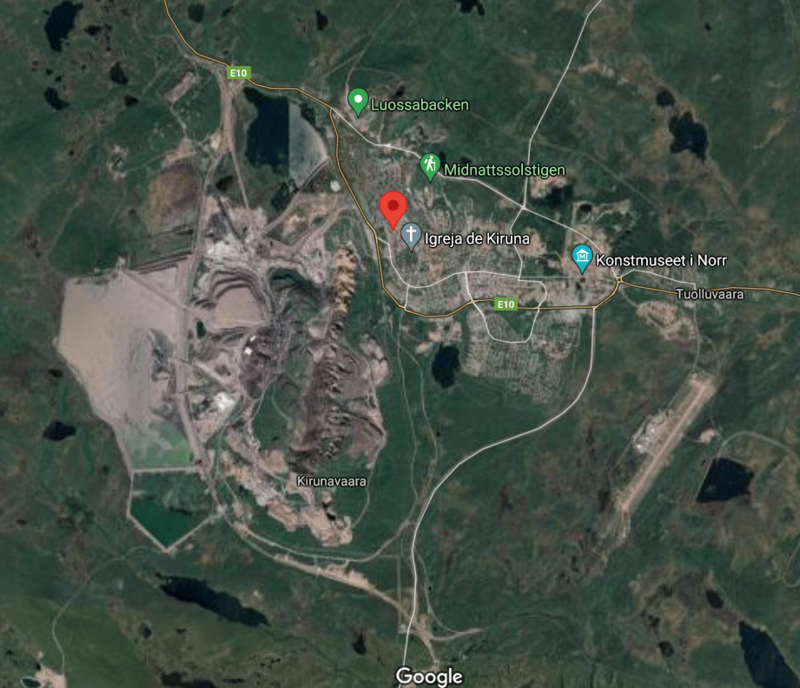

The Kiruna Mine, located within the Arctic Circle in northern Sweden, began operations in 1890 as an open-pit mine, and in the mid-1950s the transition to underground mining began. The operation, which is conducted by the company Luossavaara-Kiirunavaara AB (LKAB), focuses on process optimization, relying on automated systems and wide application of technology.

Since its implementation, an extensive infrastructure has been implemented at the site to meet the production, which was around 27.5 million tons/year of iron ore, in 2017. Currently, Kiruna mines about 80% of Europe's iron ore, which corresponded to 27.1 million tons in 2020. Thus, Kiruna is considered the largest iron producer on the continent.

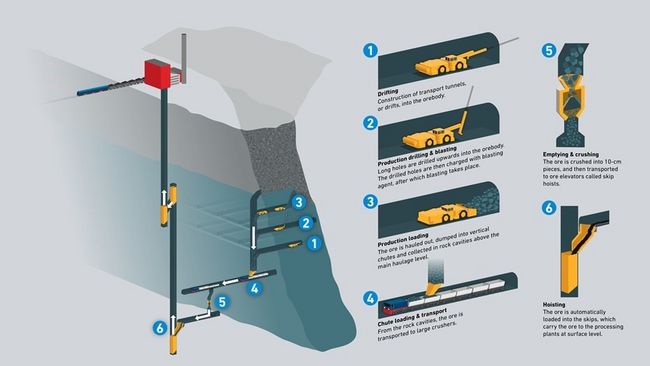

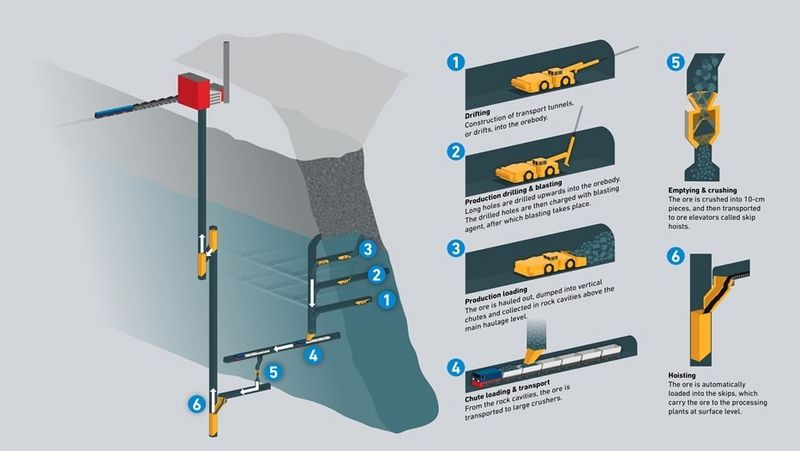

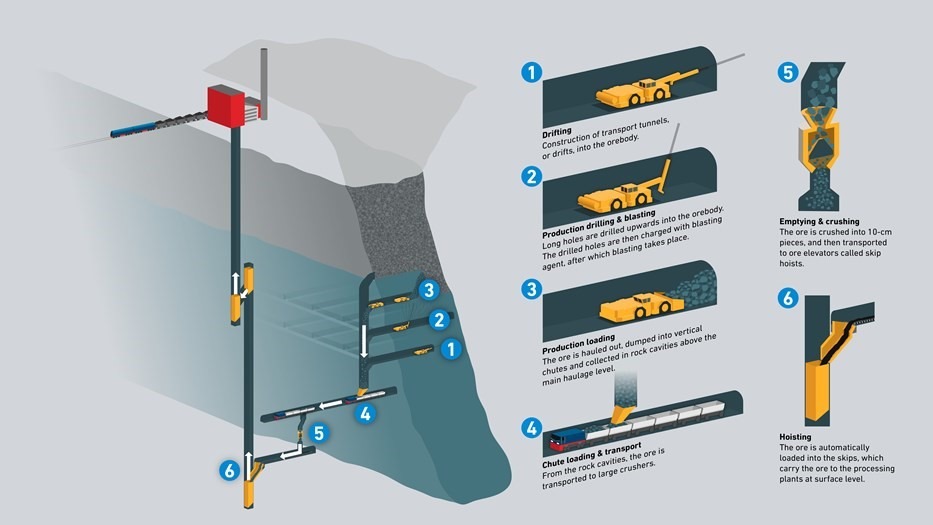

Production process

LKAB's production operations are located, in addition to Kiruna, in Malmberget and Svappavaara. The ore is extracted from LKAB's underground mines by the SubLevel Caving (SLC) method, on a large scale, on sub-levels spaced 28.5 meters vertically, and is currently 1,365 meters from the surface.

In this method, extraction is carried out by means of developed sub-levels, regularly spaced, in the ore body. SLC is a highly mechanized method, where ore is drilled, blasted, loaded, and transported to underlying levels through gravity. To learn more about the SLC method, watch this video.

The processing plants are located in Malmfälten, where the mined ore is destined for comminution, concentration and pelletizing. Finally, the products are transported by rail to the ports and distributed to the various customers.

Regarding the annual production in Kiruna, in 2017, about 27.5 million tons of ore exploited, produced 15 million tons of pellets. According to LKAB, in 2020, 27.1 million tons of iron ore products were produced in its operations.

Automated operations

The Kiruna mine is reported as a world highlight for its pioneering spirit and innovation, especially with regard to the use of remotely controlled equipment. With this focus, digital systems are developed for the various operations of the production process.

Thus, you have drilling equipment, LHDs and wagons, remotely controlled, widely used in Kiruna. Drilling is performed by a remote-controlled drilling unit, which is operated and monitored by operators in a control room. In addition, the injection of explosives into the holes is carried out by robots. After detonation, LHD's transport the extracted ore, supplying the wagons that operate at level 1. 365 meters, underground.

Since 2008, new methods have been developed for dynamic rock reinforcement, and important new systems for recording and analyzing seismic activity have been installed. In addition, LKAB was a pioneer in underground wi-fi, with the largest system in the world today. As a result, wireless communication systems were previously developed, and today they are used from applications for cell phones and tablets to driverless trucks. In short, Artificial intelligence (AI), augmented reality (AR), driverless vehicles are realities in Kiruna.

Autonomous Equipment in Kiruna

The demand for robust, automated equipment is borne by large equipment companies, such as ABB, Combitech, Epiroc and Sandivik.

ABB mainly works with electrification and delivery of automation platforms. As a result, energy-efficient systems are deployed in the electric vehicles, supplied by Epiroc and Sandivik, including battery solutions and flexible electrical infrastructure. Combitech is active in the areas of mine automation and digitalization. Among the equipment used, the Simba long hole drill and the Toro LH625iE loader from Sandivik can be highlighted.

Long-hole drills, called Simba, are used in Kiruna, and are equipped with multiple functions, allowing remote operation in a variety of ways. They also have sensors for angular inclination. In addition to production drilling in highlights, Simbas are successfully used for slot drilling and for some auxiliary drilling. The following video shows Simba in operation.

Sorry, this video can not be played because of your privacy setting.

You can change your settings here anytime.

Watch the video below to learn how Sandvik's Toro loader works.

Sorry, this video can not be played because of your privacy setting.

You can change your settings here anytime.

It is worth noting that the production of the drilling machines can continue to operate without operators during shift changes, lunch breaks and night shifts. Thus, we have that the control of the operation is carried out through the control rooms.

Finally, we'll talk about the largest capacity electric loader, the Toro LH625iE, from Sandvik. The equipment has been customized to meet Kiruna's demand, including improved energy efficiency, advanced technology, latest digital solutions and smart connectivity.

LKAB 5.0 Project: The sustainable mining of the future

LKAB 5.0 is an LKAB project, focused on building a new world standard for deep-sea mining. Aiming at an evolutionary change, the expectation of the project is to establish a new concept of mine of the future, free of carbon dioxide, digitalized and autonomous.

The project began in June 2018, following the same precepts adopted over the years, with an even greater focus on being at the forefront of technological development. With the improvement of the mining, processing and logistics systems, LKAB intends to design an infrastructure for the future, being the basis for a new production system at great depths. Learn more about the project.

In this way, LKAB in partnership with ABB, Epiroc, Combitech and Sandvik, aims to develop this industrial project to achieve the goal of a sustainable mine by 2030, making operations even more technological and autonomous. Watch ABB's video about the project here.

An example of equipment designed by Epiroc is the Boomer M2, a rugged, battery-powered drilling jumbo. The following video shows how it works.

Reconstruction of Kiruna

After more than 100 years of ore extraction in the underground galleries, Kiruna has entered a reconstruction process. With the advances of the activity at depth, cracks appeared in the constructions and buildings in the city of Kiruna, near the mine, caused by the subsidence of the soil.

In 2014, the city began to be relocated to a new location, about two miles to the east, and this process is expected to end in mid-2034. As a result, buildings will be moved, raised and relocated, or dismantled and rebuilt. Learn more about the project in the video below.

Sorry, this video can not be played because of your privacy setting.

You can change your settings here anytime.

In a project of such importance to the city and local economy, those involved include urban planners, landscape architects, biologists, civil engineers, construction experts and contractors.

An exhibition at Stockholm's national centre for architecture and design (ArkDes), has drawn the world's attention to urban planning for the city's relocation. The "Kiruna Forever" exhibition analyzed this change through more than 100 works by architects, urban planners and artists. The exhibition is temporarily closed, but part of the exhibition can be explored online here.

Interested in the subject? Check out other texts on our blog!

References:

- LKAB website

- Utopia Village

- Epiroc website

- Sandivik website

- Atlas Copco Underground Mining.