Industry 4.0 aims to make industrial production processes more efficient through the prioritization of innovative research activities, digitalization of production, sustainable energy management, development of innovative working environments, smart mobilities, and information security.

In Brazil, in 2018, the then Ministry of Development, Industry and Foreign Trade (MDIC) and the Ministry of Science, Technology, Innovation and Communications (MCTIC) published Industry 2027. This project evaluates how advances in industrial technologies impact different sectors of the Brazilian economy, including mining.

In this context, the concept of Mining 4.0 emerges, which unites the principles of Industry 4.0 with mining. Want to know more about this subject? Continue reading this text in which we will address examples, benefits and the current panorama of the new mining model.

What is Mining 4.0?

The concept of mining 4.0 involves accessing mineral resources in a safer and more sustainable way through the use of technologies and processes adopted by Industry 4.0. Among the innovations and applications of mining 4.0 provided are:

Drones

The use of drones in mining has several applications, such as obtaining three-dimensional data of the terrain, calculating the volume of irregular piles more accurately, in addition to inspecting the safety conditions of the dam and the mine in operation. Another benefit of using this technology is the monitoring of environmental preservation areas.

Autonomous Mining

One of the main innovations of Mining 4.0 is the implementation of automated systems, responsible for increasing the productivity of mines, in addition to providing safer operations, reducing the exposure of operators to the daily risks of a mine.

In this field, the case of Kiruna stands out, which is an example of autonomous and modern mining. The Kiruna mine is located within the Arctic Circle, in northern Sweden and stands out in the use of technologies, mining about 80% of Europe's iron ore. Learn more about this case and the mine's production processes in our text: Automation in Mining: Kiruna Case.

Currently, autonomous mining also stands out with regard to the use of autonomous vehicles. In this method, the vehicles are controlled by computer systems, GPS, radars and artificial intelligence. Among the benefits are the reduction of fuel costs, maintenance and better safety effectiveness, since the system is able to identify obstacles and trace new routes.

In the video below, you can see a real-world example of the use of autonomous vehicles developed by Sandvik:

Sorry, this video can not be played because of your privacy setting.

You can change your settings here anytime.

Artificial intelligence

The implementation of artificial intelligence in mining can be seen in the development of autonomous vehicles, such as trucks and excavators, but it is also present with regard to the useful life of equipment.

Artificial intelligence allows the analysis of a high volume of data, making it possible to generate insights into the behavior of equipment. Thus, the systems are able to optimize the life cycle of the equipment and therefore reduce maintenance costs.

With the use of this methodology, Vale increased the useful life of truck tires by 30% at the Salobo/Pará mine. The project resulted in savings of US$ 5 million in one year for the mining company.

Sorry, this video can not be played because of your privacy setting.

You can change your settings here anytime.

Benefits of Mining 4.0

There are several benefits provided by Mining 4.0. Check out some below:

Sustainability

Sustainability and concern for the environment are the focus of the new technologies used by mining companies. Currently, there are sectors integrated with video analytics software that, based on data analysis, allow the projection of possible problems and trigger preventive alerts for technical teams and specialized in monitoring high-risk structures. This technology can be used, for example, in the more effective monitoring of tailings dams, reducing the chances of environmental impacts.

Productivity

One of the main advantages in the implementation of Mining 4.0 tools is the optimization of processes and equipment, generating a reduction in production costs and an increase in machine efficiency. All of this contributes to more sustainable and profitable mining.

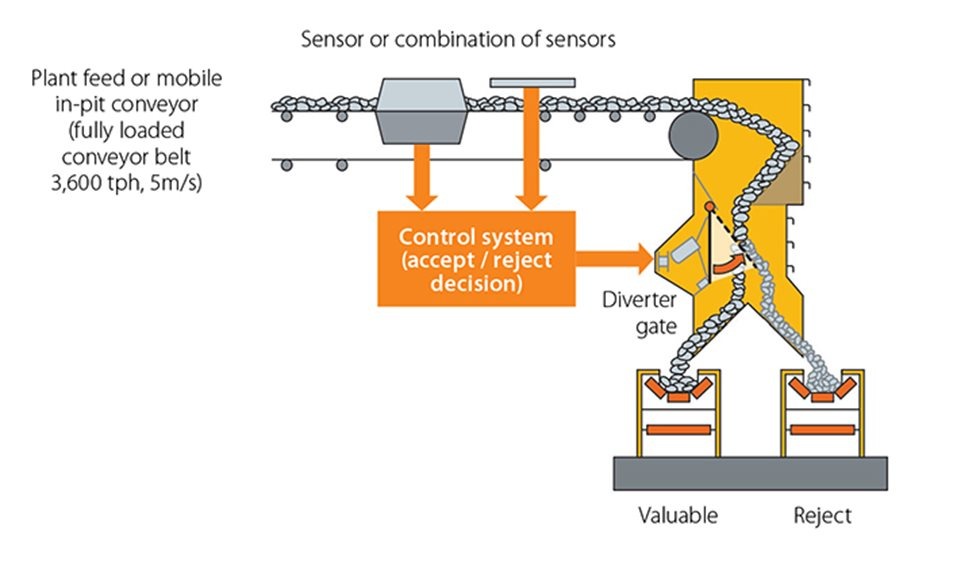

Another technology allied to productivity is Ore Sorting. Among its functionalities, the equipment applies color, transparency, size and shape sensing, separating the material between ore and waste rock in an automated way. In this method, compressed air jets are used instead of water, reducing water consumption.

Safety

Increasing the safety of operations is one of the objectives of Mining 4.0. The innovations mentioned above, such as autonomous vehicles and dam monitoring systems, are intrinsic to improving safety and reducing serious accidents in the mining work environment.

Mining 4.0 Overview

The new mining model is already a reality in Brazil. Mining companies such as Vale and Rio Tinto are increasingly advancing in the implementation of automated and control systems. There is also the Industry 2027 Project, which estimates an increase in the diffusion of Mining 4.0 in Brazil by 2027.

In addition, there is an expectation that, in the near future, 5G Internet will corroborate Mining 4.0 This is because this technology has several evolutions, such as the ability to cover large distances, high speed, high power (data volume) and low latency (shorter response time). In this way, the most remote areas of mining would have access to high-speed internet, which contributes to the use of the artificial intelligence systems mentioned above.

Mining 4.0 is a viable alternative to mining challenges, including reducing energy costs, creating safe work environments, and reducing environmental impacts. Also, in addition to the efficiency of the processes, mining 4.0 seeks benefits to the surrounding communities and the environment, since mining activity directly affects the economy and quality of life of the places where it is in operation.

Did you like this text? Visit our blog for more content like this!

References

http://repositorio.ufu.br/bitstream/123456789/28296/4/ImpactosInd%c3%bastriaMinera%c3%a7%c3%a3o.pdf

https://www.green4t.com/insights/mineracao-4-0-e-os-desafios-para-ter-operacoes-mais-sus

http://www.vale.com/brasil/pt/initiatives/innovation/industria-40/paginas/default.aspx

https://armac.com.br/blog/mineracao/mineracao-4-0/

https://tecnicoemineracao.com.br/mineracao-4-0/

https://diariodocomercio.com.br/opiniao/mineracao-4-0/

https://www.minasjr.com.br/mineracao-4-0/

https://miningdigital.com/smart-mining/mining-40-how-innovation-shaping-mines-future