The Ruhr Valley in western Germany, an important industrial region in Europe, was dominated by coal mines and steel mills from the second half of the 19th century to the end of the 20th century.

Mining in the region began in the southern portion of the Ruhr Valley, where coal is exposed in the upper coal outcrops. In the thirteenth century, coal was extracted in shallow wells and later in primitive galleries. The use of shafts began in the eighteenth century, even before the invention of the steam engine that allowed pumping in coal mines, thus enabling mining at greater depths.

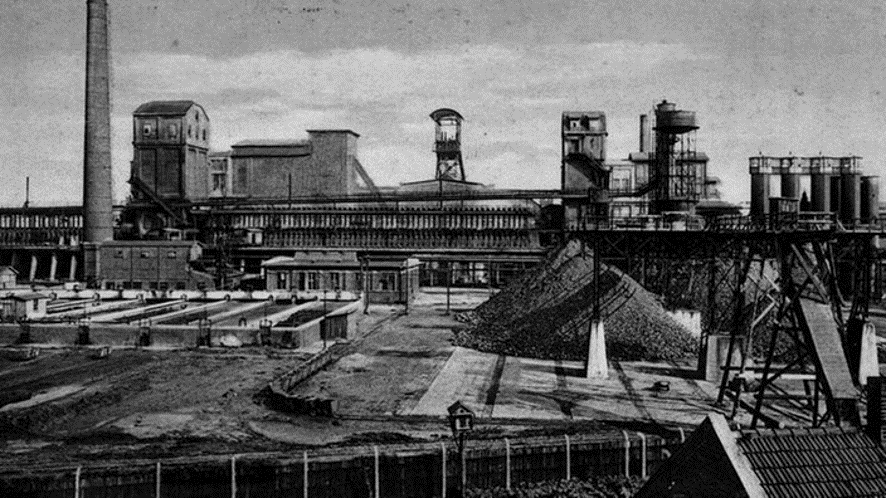

From then on, the Ruhr Valley went from a rural area to the famous industrial region with its coal mines, with the development of railways and steamboats, as well as the establishment of steel mills in the second half of the nineteenth century. At the same time, coal mining gradually moved northwards into the central part of the floodplain of the "Emscher" River, already reaching the "Lippe" River in the north of the Ruhr Valley.

For almost 200 years, the Ruhr Valley remained the industrial center of Germany and one of the most important industrial regions in the world.

Zollverein's story is closely linked to the name Franz Haniel. In 1840, the metallurgist and owner of the Ruhrort coal mine acquired the first mineral rights to the site, and in the Zollverein area were found mineral bodies of greater power.

The entrepreneur is also a partner in the company Jacobi, Haniel & Huyssen, which later became Gutehoffnungshütte, the largest manufacturer of machinery and systems in Europe. The company produced almost everything industrialization needed: steam engines and ships, locomotives, rails, and bridges. And for that it needs coal. In 1847, Mr. Franz Haniel and his eight sons were the sole owners of the area, which totaled 13.8 square kilometers, and which they called "Zollverein". The Haniel family remained the sole owners of Zollverein until 1920.

In 1920, the Haniel family of Zollverein formed a business group with Phönix AG with a focus on mining and metallurgy. In 1926, Phoenix AG, and with it Zollverein, was merged into Europe's largest mining group at the time, Vereinigte Stahlwerke AG.

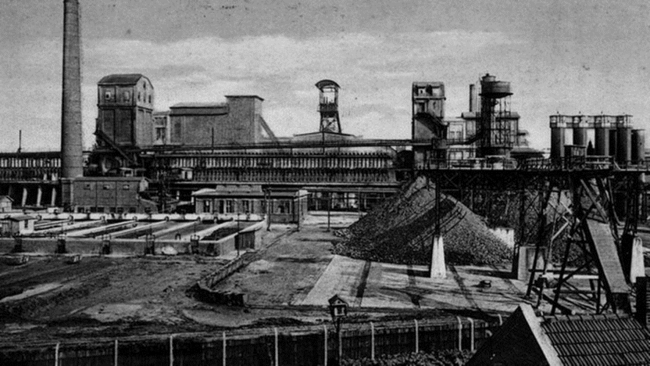

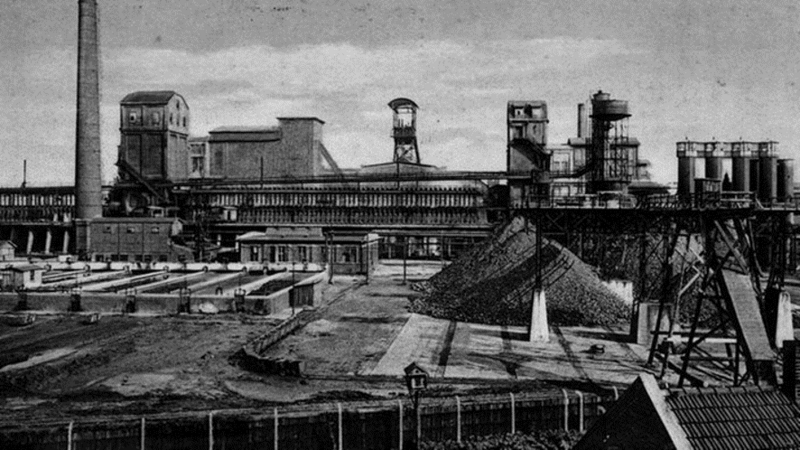

The entire Zollverein mine complex was modernized in the 1920s. The highlight of the planned renovation is the new central axis, which was designed by architects Fritz Schupp and Martin Kremmer, who would later become Germany's most important industrial architects.

After 1920, the mechanization of mining, and especially the demand for energy and steel, just before World War II, led to the highest coal production in the history of the Ruhr Valley in 1939 (130 Mt) and a total number of 151 coal mines in the region. Until the 1950s, coal remained the dominant source of energy and also became an important raw material for the chemical industry. After World War II, coal production increased rapidly and reached its peak in 1956 (124 Mt).

Due to oil and gas competition in the energy market, coal mining in the Ruhr district experienced a major downturn from the early 1960s onwards. In 1964 alone, 13 mines were closed in Essen, the number of miners decreased from 54,413 (1958) to 9,771 (1978).

THE IMPORTANCE OF THE ZECHE ZOLLVEREIN MINE IN THE WARS

In addition to being a fundamental raw material for the world economy from the First Industrial Revolution, when the steam engine began to be used in manufacturing production, coal also had great importance during the great wars.

Coal will have a place in Germany's energy matrix, especially in relation to the country's military bases, and will play a founding role both in the period preceding the outbreak of the First and Second World Wars and in the course of the conflict, in which obtaining and maintaining sources of the resource will prove to be high priority objectives.

During wars, coal production at the Zollverein mine stands out mainly as a source for the production of steel, weapons and ammunition, being an essential raw material in both the energy and steel industries.

In 1914, on the eve of the First World War, Zeche Zollverein expanded its structures by creating new extraction axes and new coke plants put into operation. This year, coal production reached about 2.5 million tons.

THE CLOSURE OF THE ZECHE ZOLLVEREIN MINE

The Zollverein mine operated until 1986, producing about 240 million tons of coal. To reach this mark, mining was carried out by the Longwall method and was operated by more than 8 thousand miners day and night in extreme conditions.

The Zollverein Mine Closure involved a major decommissioning effort of machinery and equipment. One of the main challenges of the mine closure involved the drainage plan for the area and the expansion of the pumping stations.

Since the mid-nineteenth century, the Longwall underground mining method has been introduced in the Ruhr district. This method is indicated for the ploughing of bodies with a large lateral extension and a constant thickness.

Longwall represents one of the safest methods for mining at great depths, with the main advantage of allowing controlled subsidence, which can be accurately pre-assessed in terms of magnitude, effects and duration. The application of this method is the reason for the extensive subsidence observed in the Ruhr Valley.

The mining of more than 200 million tons of coal in Zollverein has caused the earth's surface level to drop by more than 25 meters in some areas. In addition, Zollverein is situated in the Emscher zone, where many swampy areas already existed before mining began, and the subsidence caused by mining has worsened these water flows significantly.

Thus, at approximately 1000m depth, a central pumping station is kept in operation, which pumps about 1,200 m³ of water from the mine to the surface every day. This process occurs in a similar way in several other mines in the Ruhr Valley; approximately 38% of the Emscher watershed and 15% of the Lippe watershed are artificially drained. If the pumping stations in these areas were closed, most of the Ruhr district would be flooded

In Zollverein, the future use of the space was widely discussed with society, which decided to list and conserve the site in order to maintain the facilities that document the production process, how the miners worked and lived.

Today, the architectural ensemble built at the Zeche Zollverein Mine demonstrates that the transition from industry to culture has been masterfully accomplished. After the listing, the entire mine closure was transformed into a large stage that keeps alive the history of mining and the development of industrial architecture.

The cultural itineraries, the architectural ensembles and all the history portrayed within the Zollverein Mine Complex can be found in our article "Zollverein Coal Mine Complex: the transformation of a mine closure into a large architectural ensemble", where we tell you a little about the incredible cultural experience provided at the site.